The Sundyne API 610, OH3 with Cartridge Seal API-682 Direct Drive Pump

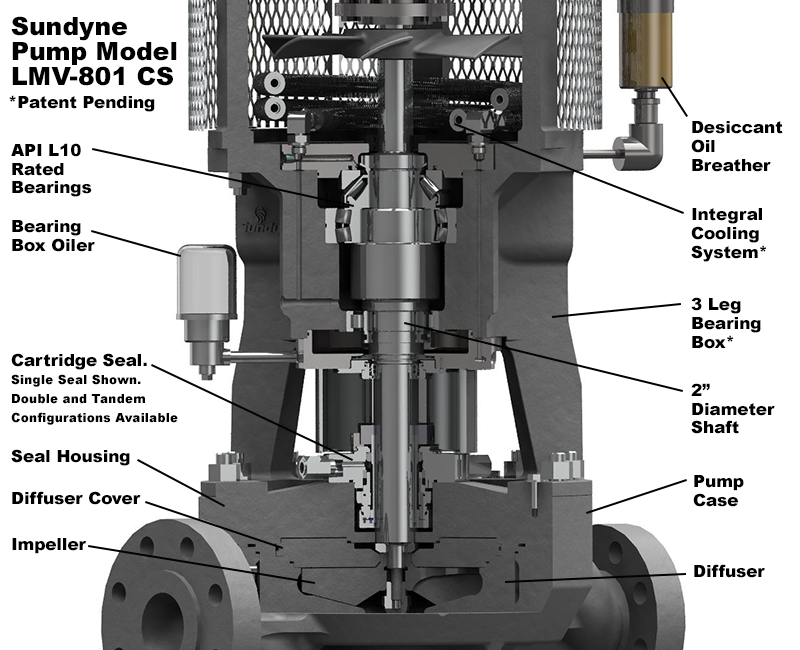

The Sundyne LMV 801CS (Cartridge Seal) is a self-contained unit consisting of a shaft sleeve, seal and gland plate that fits onto the pump shaft as a single assembly. The cartridge seal design eliminates many common causes of seal failure and it helps operators overcome the fitting and installation problems associated with conventional seals.

The compact and rugged API 682 cartridge seal is designed specifically for the Sundyne LMV 801, providing operators and maintenance engineers with an economical alternative to standard seal configurations, in a convenient package that eliminates errors in installation.

- Flows to 380 gpm (86 m³/hr)

- Heads to 720 ft (220 m)

- Suction Pressure 875 psi (60 bar)

- Temperature Range -40 to 550°F (-40 to 288°C)

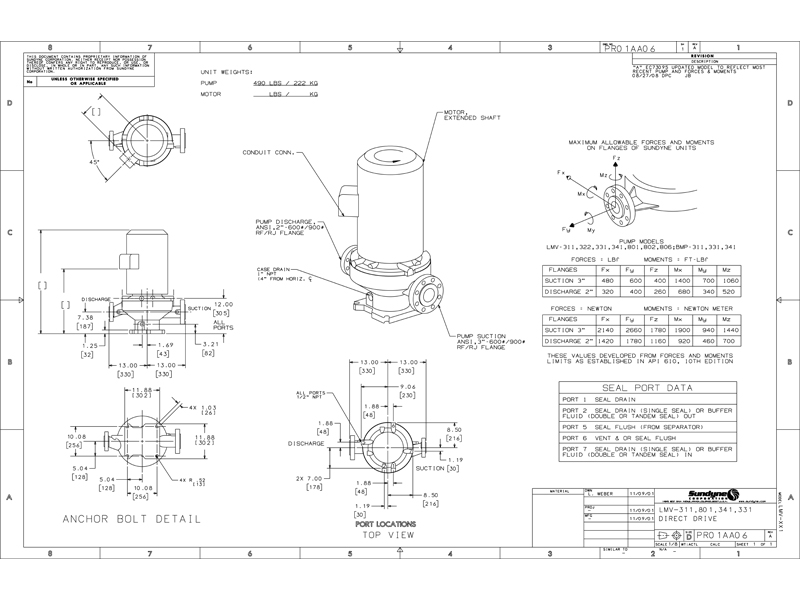

The vertical configuration of the direct drive line of Sundyne pumps are specifically designed to save valuable space in refineries, NGL production, petrochemical and chemical plants.

APPLICATIONS

- Feed pumps

- Booster pumps

- Bottoms pumps

- Wash water pumps

- Reflux pumps

- Condensate pumps

Proven to be reliable, safe, compact and efficient, Sundyne LMV 801CS pumps provide a number of operational benefits:

- Single stage, vertical in-line overhung pump according to ISO 13709/API 610 OH3 design recommendations

- Faster, easier and error-free replacement of pump shaft seals with industry standard cartridge seal

- Cartridge seals can be installed on any existing LMV 801 without changing piping or wet end components

- Eliminates premature failures due to improper installation of seals

- Less downtime for maintenance

- Increased durability and reliability with cartridge seals

- Maximized up time

- Saves space-25% the size of competing horizontal pumps

- API 610 OH3

- ATEX certified

- Continuous operations for 5 years with no overhaul

- Upgradable to cartridge seal API 682

- Barske impeller low NPSH technology

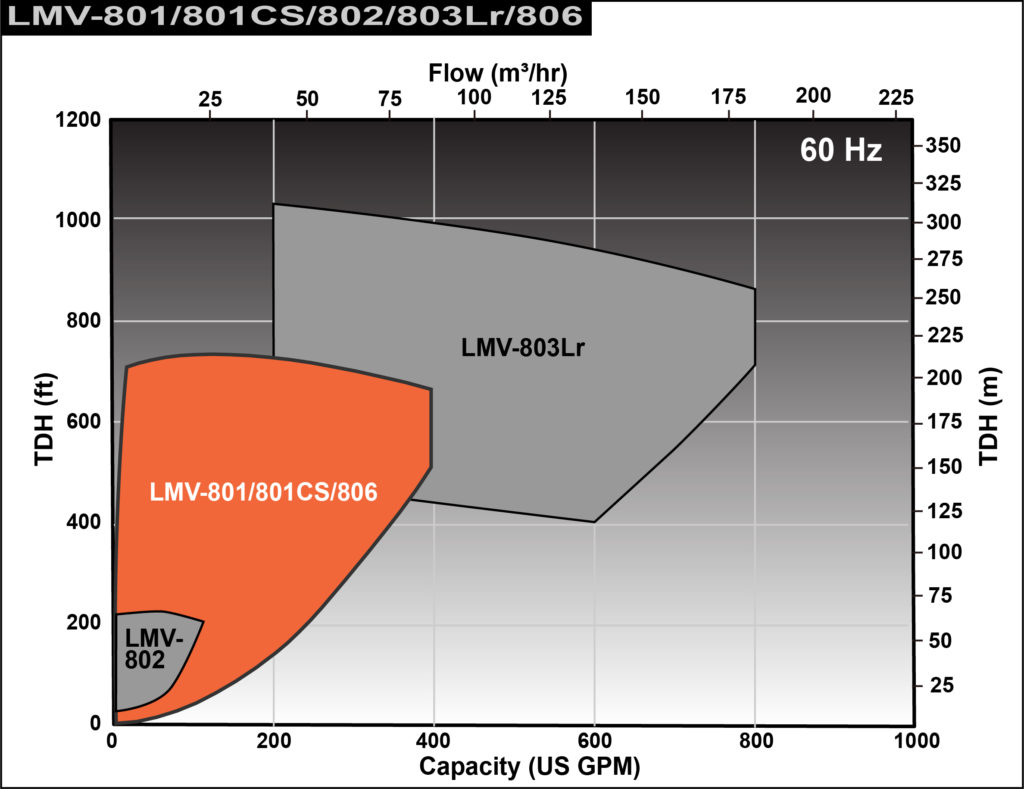

US 60 Hz

- Heads to 720 ft

- Flows to 380 gpm

- Standards API 610 OH3

- Maximum Motor Power 75 HP

- Temperature Range -40 to 550°F

- Maximum Allowable Working Pressure 1,440 psi

- Maximum Suction Pressure 875 psi

- Maximum Viscosity 750 cp

- Solids Range 0.015″

- Mounting Configuration Vertical

- Seal Configurations Single, Double, Tandem-API 682 Cartridge

- Available Inducer Yes

- Available Flanges 600#, 900# ANSI RF

- Suction and Discharge Size 3″ x 2″

- API Plans 11, 13, 14, 21, 31, 32, 41, 52, 53, 54, 61, 62

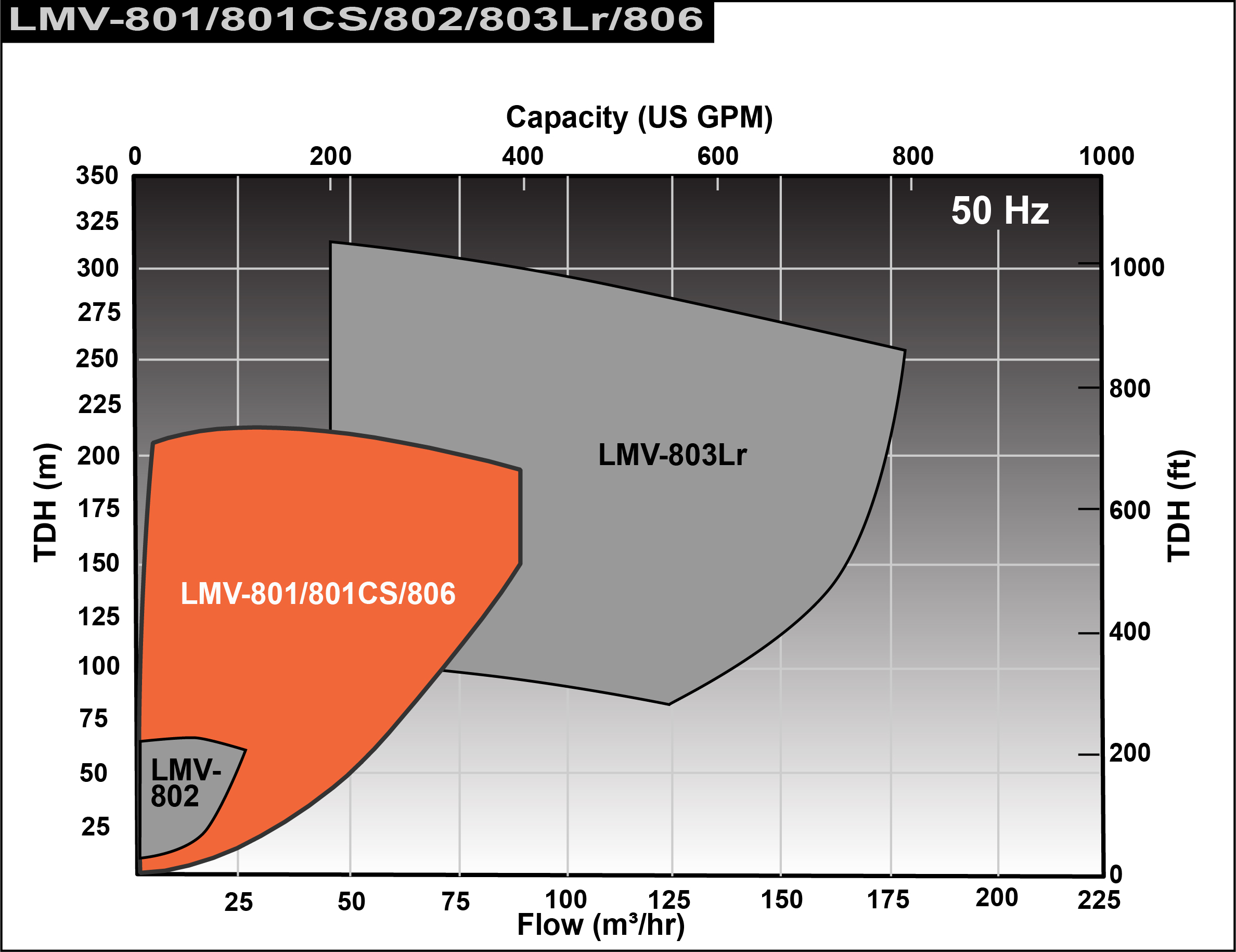

Metric 50 Hz

- Heads to 153 m

- Flows to 69 m3/hr

- Standards API 610, OH3

- Maximum Motor Power 55 kW

- Temperature Range -40 to 288°C

- Maximum Allowable Working Pressure 100 bar

- Maximum Suction Pressure 60 bar

- Maximum Viscosity 750 cP

- Solids Range 400 microns

- Mounting Configuration Vertical

- Seal Configurations Single, Double, Tandem-API 682 Cartridge

- Available Inducer Yes

- Available Flanges 600#, 900# ANSI RF

- Suction and Discharge Size 3″ x 2″

- API Plans 11, 13, 14, 21, 31, 32, 41, 52, 53, 54, 61, 62

|

LMV 801CS BUILD CODES |

A |

E |

J |

O (1) |

W |

|

API 610 BUILD (2) |

S-5 (3) |

A-7 (4) |

S-8 (4) |

N/A |

S-9 (4) |

|

Pump Case |

C.S. |

316 SS |

C.S. |

316 SS |

Monel Clad C.S. |

|

Case Studs |

B-7 |

B-7 |

K-Monel |

||

|

Seal Housing |

C.S. |

316 SS |

Monel |

||

|

Separator |

316 SS |

316 SS |

316 SS |

316 SS |

Monel |

|

Diffuser Insert |

C.S. |

316 SS |

Monel |

||

|

Diffuser Cover |

C.S. |

316 SS |

Monel |

||

|

Impeller |

316 SS |

316 SS |

316 SS |

316 SS |

Monel |

|

Impeller Bolt |

316 SS |

316 SS |

316 SS |

K-Monel |

|

|

Inducer |

316 SS |

316 SS |

316 SS |

316 SS |

Monel |

|

Tab Washer |

316 SS |

316 SS |

316 SS |

316 SS |

Monel |

|

Shaft Sleeve |

316 SS |

316 SS |

316 SS |

17-4 PH |

Monel |

|

Throttle Bushing |

316 SS |

316 SS |

Monel |

||

|

Metal Seal Parts |

316 SS |

316 SS |

Monel |

||

|

Stationary Face |

Binderless Carbon or Silicon Carbide |

||||

|

Rotating Face |

|||||

|

Shaft (all) |

4140 Steel to 0° F, 15-5 from 0° F to –240° F. |

||||

|

O-rings |

As Required |

||||

- “O” build temperature range 0 to -240°F (115°C) Pressure capability is reduced due to strain hardened pump case studs. Contact Application Engineering.

- See Sundyne Corporation exceptions/clarifications to API 610, 11th Edition for material requirements of pump parts.

- Impeller is upgraded to 316SS. A seal gland is not required because the seals mount in the seal housing. O-rings are used instead of a case gasket.

- A seal gland is not required because the seals mount in the seal housing. The pump shaft is AISI 4140 because it is not exposed to the fluid. O-rings are used instead of a case gasket.

- Diffuser Inserts and Diffuser Covers apply to model LMV-801 only.

Sundyne LMV 801CS Cutaway Poster – PDF

Sundyne LMV 801CS Data Sheet US – PDF

Sundyne LMV 801CS Data Sheet A4 – PDF

Sundyne Direct Drive API OH3, OH5 Centrifugal Pumps Brochure US – PDF

Sundyne Direct Drive API OH3 and OH5 Centrifugal Pumps Brochure A4 – PDF

Sundyne The Vertical Experts Brochure US – PDF